Key Points

- Dedicated EV platforms enable a more spacious interior, larger batteries, less wasted space

- Allows car brands to use and scale platform on multiple-sized EVs with less effort and money

- Also called ‘ground-up’, 'skateboard' or ‘bespoke’ EV architectures

Drastically reduced parts and the simplicity of electric vehicles provide new opportunities for car design and manufacturing.

Dedicated EV platforms are often mooted as a key advantage and selling point, but what advantages do they bring and which key car brands offer one?

What is a dedicated EV Platform?

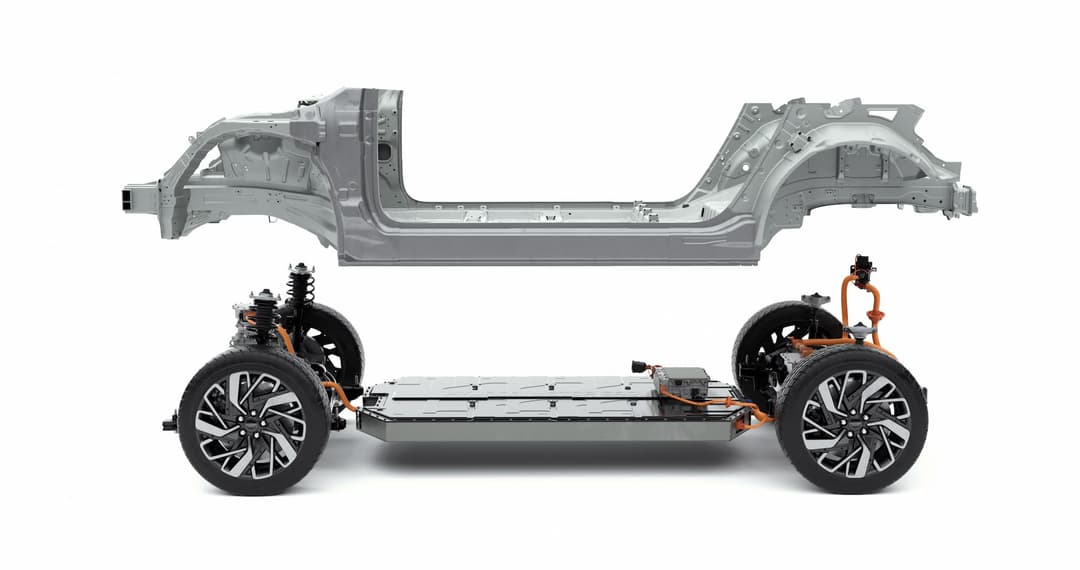

A vehicle platform is a base layer structure, where components such as the body, drive unit, and suspension are built upon or fitted into the platform.

Therefore, a dedicated electric vehicle platform is an underpinning that is designed and made from the start for EVs in mind only.

Also dubbed ‘ground-up’, ‘skateboard’ or ‘bespoke’ EV architectures, it’s designed to accommodate electric drive units, the large battery pack, and other climate control, electronic and battery management systems to yield benefits for drivers and passengers.

✅Pros of a dedicated EV platform

The key advantage of ground-up EV platforms is the skateboard design, which is a flat plane to better house the battery and electric motors. Example electric cars include the Tesla Model 3 sedan, Hyundai Ioniq 5, and Volkswagen ID.4 SUVs.

Since EVs contain significantly fewer moving parts than petrol or diesel engined vehicles – around 20 versus 2000 respectively, according to Forbes – there is more space to pack hardware components.

This enables electric car models to offer a more spacious interior with a flat and open floor thanks to stretching the wheelbase (the distance between the front and rear wheels) further than conventional internal combustion engine (ICE) cars in a comparable class size.

It also means car manufacturers can pack more battery modules with more space available to utilise, reduce unnecessary weight and therefore improve efficiency. This increased efficiency can result in more driving range. This weight-saving and efficiency improvement is evident in the below comparison between two similarly sized SUVs.

Due to the lack of an engine at the front, bespoke EVs can have a shorter bonnet or overhang, while some may offer a ‘frunk’ storage space instead.

But, it’s worth noting that some ICE platform-based models also offer this feature, such as the Kia Niro EV small SUV, Polestar 2 liftback and Ford F1-50 Lightning ute – whereas ground-up EVs such as the GWM Ora, BYD Atto 3, and Mercedes-Benz EQE sedan don’t.

The simplicity and modularity of EV underpinnings allow car designers to experiment with the different proportions and adopt the same architecture on other smaller and larger segment vehicles more easily. For car manufacturers, this reduces development times and investment costs.

And, since they’re designed for EVs only, it could also result in improved driving dynamics, better structural rigidity, and a lighter overall weight due to optimised packaging.

❌Cons of a shared EV/ICE platform

The key weakness for EV models that have been adapted on a conventional ICE platform is the inefficient packaging of internal space. Examples include the MG ZS EV, Polestar 2, and Mercedes-Benz EQA electric cars.

This results in a shorter wheelbase and less interior space in contrast to a ground-up EV platform, but comparable to a conventional petrol or diesel car architecture.

Depending on the model, there may potentially be some ICE remnants, including a rear row centre transmission hump, reduced boot space and a higher floor due to packing the batteries, and an underutilised or larger-than-needed front bonnet area.

Table by Danny Thai

However, it’s worth noting that some shared EV-on-ICE models have been designed from the start to offer a battery-electric version or have been adapted better, and may not suffer as noticeable disadvantages.

Electric models such as the MG ZS EV still offer a near-flat floor and good legroom in our tests, the Volvo XC40 Recharge provides a sizable frunk and claimed optimised structural rigidity, and the Genesis Electrified GV70 utilises an 800-volt class charging architecture.

Carmakers have also poured more money into developing dedicated EV platforms, so they are often more expensive to buy right now.

Tesla EV Platform

Model 3/Y

Tesla’s second-generation dedicated EV platform underpins the popular Model 3 electric small sedan and Model Y electric medium SUV.

It was introduced with the former in 2017 and allowed the American car and technology company to offer sub-$100,000 electric car models – which have quickly become the best-selling EVs globally.

Both the Model 3 and Model Y are available in single-motor rear-wheel drive and dual-motor all-wheel drive configurations, with the latter allowing the Tesla EVs to charge up to 250kW DC speeds for the first time.

Model S/X

Tesla’s first-generation ground-up EV platform is used in the Model S large sedan and Model X three-row SUV.

It debuted in 2012 with the Model S, as the company’s first bespoke electric model, and then the Model X joined in 2015. It emphasises an efficient aerodynamic design, high-performing electric motors, fast DC charging, and large long-range batteries – previously unheard of at the time.

The Model S and Model X are positioned as luxury electric vehicles priced in the $100,000 and $200,000 range and are still sold today, with a major refresh introduced in 2021.

BYD EV Platform

E-Platform 3.0

The Build Your Dreams (BYD) third-generation dedicated EV platform was introduced in 2021 and is the base for BYD electric car models such as the Atto 3 small SUV, Dolphin small hatchback, and Seal sedan.

The highlight of the bespoke architecture is it integrates the Chinese conglomerate’s proprietary and durable lithium-iron-phosphate (LFP) Blade Battery modules into the structure of the vehicle body, which results in improved torsional rigidity.

BYD e-Platform 3.0 is also capable of 800-volt class charging, all-wheel drive, and up to 1000km driving range on the lenient NEDC testing cycle. However, current BYD electric cars using this underpinning don’t offer these capabilities yet.

Hyundai Group EV Platform

The Hyundai Motor Group Electric Global Modular Platform (E-GMP) was detailed in 2020 and debuted in the Hyundai Ioniq 5 medium electric SUV a year later. It underpins the South Korean brand’s portfolio of brands, including the Hyundai Ioniq 6 sedan, sporty Kia EV6 and luxury Genesis GV60 crossovers, and all future EVs such as the Hyundai Ioniq 7 and Kia EV9 large SUVs.

E-GMP brings a more advanced 800-volt class charging architecture, which means theoretical ultra rapid charging speeds at up to 350kW DC, supports bi-directional charging, and improved structural safety and cooling systems. It also claims to reduce the number of parts by 40 per cent.

The Ioniq 5 and GV60 electric cars in particular have an open driver and front passenger flat floor space thanks to the lack of a transmission tunnel, whereas the Ioniq 6 and EV6 divide both occupants with storage space underneath the centre console.

MG EV Platform

MSP

SAIC Motor’s Modular Scalable Platform (MSP), otherwise called Nebula in China, debuted in 2021 with the MG 4 small hatchback as its first ground-up EV platform – as opposed to the combustion engine platform on the MG ZS EV small SUV.

The platform can be scaled to suit a variety of body styles with 2650 to 3100 mm wheelbases, offers improved battery energy density, and claims to be safer with ‘zero’ thermal runaway risk to prevent overheating and intense fires.

For reference, the affordable MG 4 electric car is offered in two battery sizes with up to 450km claimed WLTP driving range, single- or dual-motor, and rear-wheel drive or all-wheel drive configurations overseas.

Volkswagen Group EV Platform

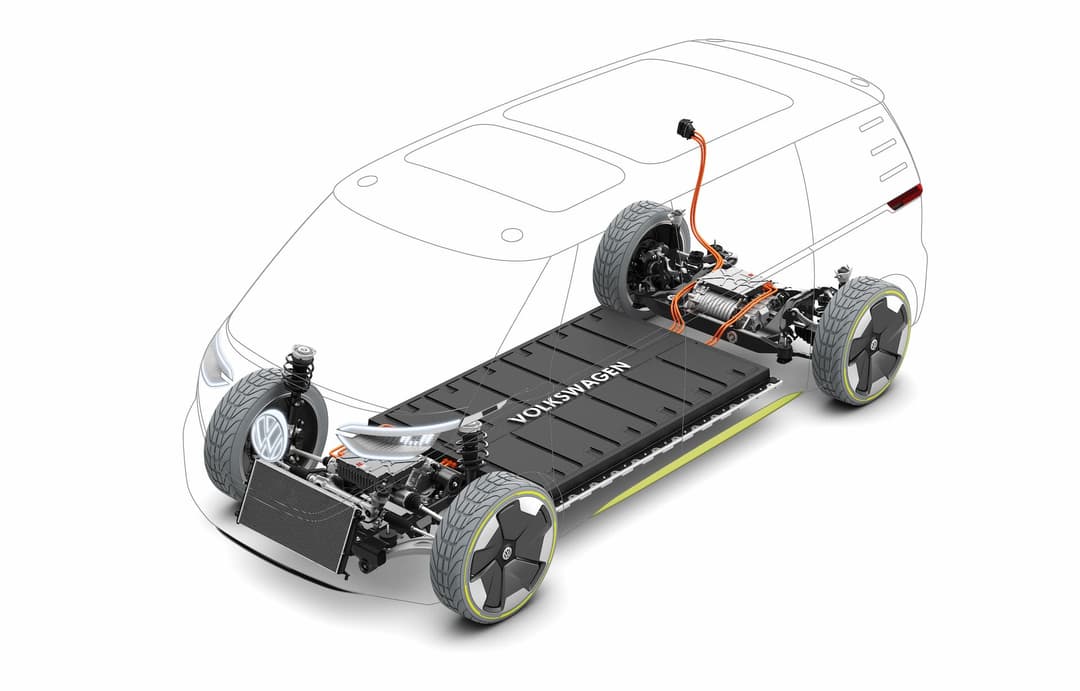

MEB

Volkswagen Group’s Modular Electric Toolkit or Modular Electric Drive Matrix (MEB) debuted in 2018 and sits beneath a range of electric cars such as the Volkswagen ID.3 small hatch, ID.4 and ID.5 medium SUVs, ID.Buzz and ID.Buzz Cargo vans, Cupra Born sporty hatch, Škoda Enyaq, and Audi Q4 e-Tron SUV overseas.

The MEB architecture enables up to 500km electric driving range, 135 to 170kW DC fast charging, a balanced weight distribution, shorter overhangs, and the electric motors sit directly on the axles. As standard, it’s rear-wheel drive or all-wheel drive with an additional front-mounted electric motor.

It’s designed to be modular, so the wheelbase, track width and battery housing can easily be scaled up and down to suit a variety of model types and sizes. Ford has also partnered with the German carmaker to use the MEB platform in two new crossover electric SUV models.

Volkswagen Group has also upgraded it with the ID.7 electric sedan debuting the MEB+ platform to offer increased 175 to 200kW DC charging speeds, up to 700km driving range, and unified prismatic battery cells to reduce costs by up to 50 per cent.

J1

The Porsche Taycan and Audi e-Tron GT electric cars sport a different dedicated ‘J1’ platform, which was introduced in 2019.

The underpinning is designed for high-performance EVs, which enables both models to utilise a two-speed transmission for faster low-speed acceleration and increased high-speed efficiency, an 800-volt class charging architecture to support up to 270kW DC rates under optimum conditions, and a rearranged battery setup to allow ‘foot garages’ for rear passengers to slide their feet underneath the front seats.

It will soon be succeeded by the Premium Platform Electric (PPE) in upcoming models such as the Porsche Macan EV and Audi A6 e-Tron, before all Volkswagen Group electric cars move to the Scalable Systems Platform (SSP) by the end of the decade.

Toyota EV Platform

e-TNGA

The electric Toyota New Global Architecture (e-TNGA) was introduced in 2020 and is the base for the RAV4-sized Toyota bZ4X, shared with the Subaru Soltera, and upmarket Lexus RZ medium electric SUVs.

While it’s modelled on its internal combustion engine TNGA architecture, this is a dedicated EV platform which is scalable in size, streamlines its product development, can house up to 100kWh battery sizes, and configurable in front-, rear-, and all-wheel drive powertrains. The three e-TNGA SUV models also boast a higher driver instrument display and a centre console storage under tray for the first time.

The new Toyota CEO Koji Sato has promised to prioritise battery-electric vehicles, with a new-generation EV platform expected in 2026.

Renault-Nissan EV Platform

CMF-EV

The Common Module Family electric vehicle (CMF-EV) platform is from the Renault-Nissan-Mitsubishi alliance and currently used by the Renault Megane E-Tech small crossover and Nissan Ariya family electric SUV overseas.

Unlike most other bespoke EV platforms in this list, CMF-EV is more flexible for each car brand to pick and choose its own parts collection, technology and software.

CMF-EV allowed Nissan to place the Ariya air conditioning unit further forward to improve interior space for the front row, open front floor space with a movable sliding centre console, and electric motors placed directly next to the axles to optimise space.

Geely EV Platform

SPA

The second-generation Scalable Product Architecture (SPA2) underpins the Volvo EX90 and Polestar 3 large luxury electric SUVs.

Both models feature large 111kWh battery packs (gross), up to 610km of range, charging at up to 250kW DC, boasts a lower floor, and are designed for full autonomous driving functions with the option for LiDAR sensors.

Geely, the Chinese automaker which owns a host of Swedish and British car brands, also has the smaller Sustainable Experience Architecture (SEA) EV platform which will be used in the current Smart #1 crossover overseas, and forthcoming Polestar 5 large flagship sedan, Lotus Electre performance SUV, and Lotus Type 133 sports sedan.

Mercedes-Benz EV Platform

EVA

The Mercedes-Benz Electric Vehicle Architecture (EVA) is the marque’s first ground-up platform used by the EQE sedan, EQE SUV, EQS sedan, and EQS SUV.

It’s designed to accommodate larger-sized electric cars to pack large 100kWh-plus batteries, up to 200kW DC fast charging rates, and emphasises an aerodynamic body design to improve energy efficiency and extend EV range.

The German automaker is set to introduce the Mercedes-Benz Modular Architecture (MMA) to fit small and medium-sized EVs in 2025, along with the MB.EA platform for medium and large cars, AMG.EA platform for high performance AMG models, and Van.EA for light commercial vehicles.

Frequently Asked Questions

About the author

Stay up to date with the latest EV news

- Get the latest news and update

- New EV model releases

- Get money savings-deal