Key Points

- BMW expands solid-state battery partnership by adding Samsung SDI to its collaboration with Solid Power

- Solid Power supplies sulfide-based solid electrolyte while Samsung SDI integrates it and builds battery cells

- BMW and Solid Power have collaborated since 2016 and tested ASSB cells in a BMW i7 prototype in 2025

- Partnership aims to accelerate commercialisation of solid-state batteries offering higher energy density and improved safety

BMW has taken another major step toward next-generation electric mobility by teaming up with Samsung SDI and Solid Power to accelerate the development of all-solid-state battery (ASSB) technology.

The collaboration aims to bring solid-state batteries, long seen as the “holy grail” of EV energy storage, closer to large-scale production and real-world use.

▶️MORE: What are LFP, NMC, NCA Batteries in Electric Cars?

A Three-Way Partnership Focused on Innovation

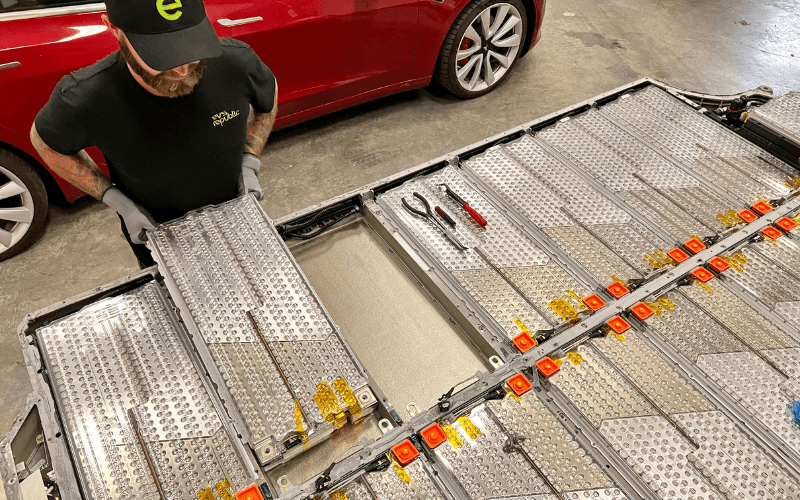

BMW and Colorado-based Solid Power have been working together on solid-state battery research since 2016. Their partnership deepened in 2022 through a technology transfer agreement, allowing BMW to run its own prototype cell production line at its Cell Manufacturing Competence Center near Munich, Germany.

Earlier this year, the duo successfully installed Solid Power’s largest-format pure solid-state battery cells into a BMW i7 technology test vehicle, marking one of the most advanced real-world tests of the technology so far.

▶️MORE: How Long Do Electric Car Batteries Last?

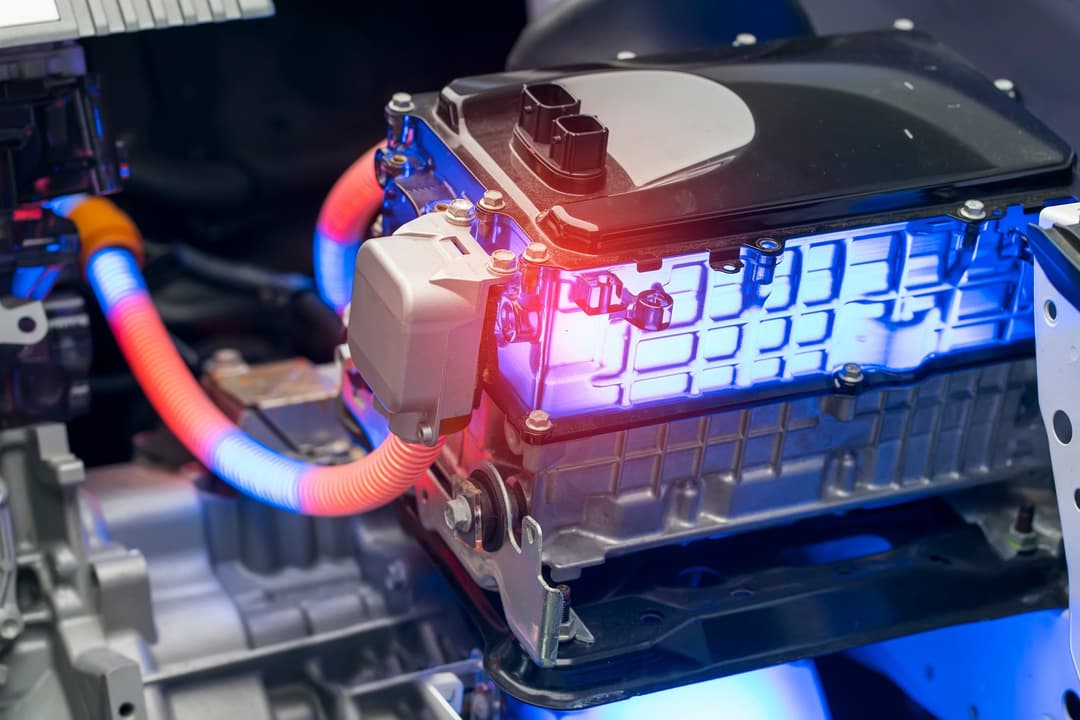

Now, Samsung SDI has joined the effort. Under the new arrangement, Solid Power will supply its sulfide-based solid electrolyte, while Samsung SDI will integrate it into separators and catholytes to produce complete battery cells. These cells will then be validated in BMW’s upcoming demonstration vehicles.

Solid Power’s CEO, John Van Scoter, said the goal is to make the technology commercially viable:

“Our solid electrolyte technology is designed for stability and conductivity. Working closely with global leaders like BMW and Samsung brings us closer to making ASSB technology mainstream.”

The Road Ahead for Solid-State Batteries

Unlike traditional lithium-ion batteries that use a liquid electrolyte, solid-state batteries rely on solid materials such as sulfides, oxides, or ceramics. The benefits are significant, including higher energy density, faster charging, improved safety, and longer battery life.

However, scaling production remains the biggest challenge. Manufacturing solid-state batteries at commercial volumes requires entirely new techniques, and few companies have yet cracked the code.

▶️MORE: Check Zecar's Electric Car Dictionary

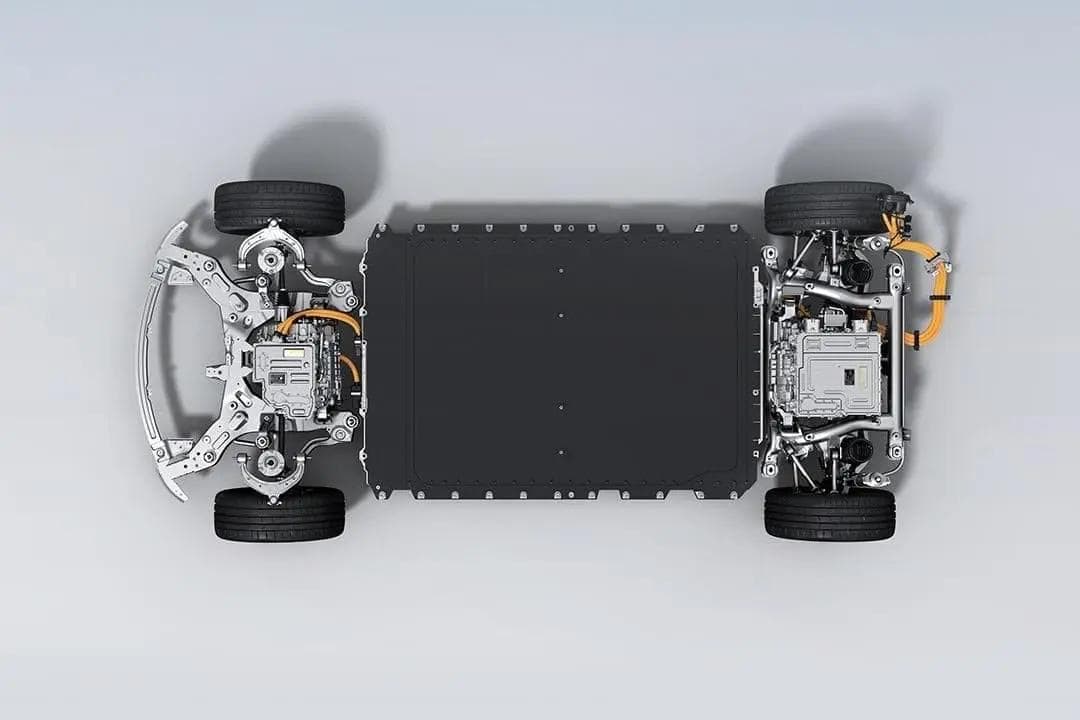

BMW, however, remains confident that commercialisation is within reach. The brand plans to showcase a demonstration vehicle powered by solid-state cells before the end of the decade, reinforcing its ambition to lead the next phase of EV technology.

Most automotive analysts predict that solid-state batteries could begin appearing in production vehicles in the late 2020s or early 2030s, though initial applications will likely be limited to premium vehicles due to higher costs.

Stay up to date with the latest EV news

- Get the latest news and update

- New EV model releases

- Get money savings-deal