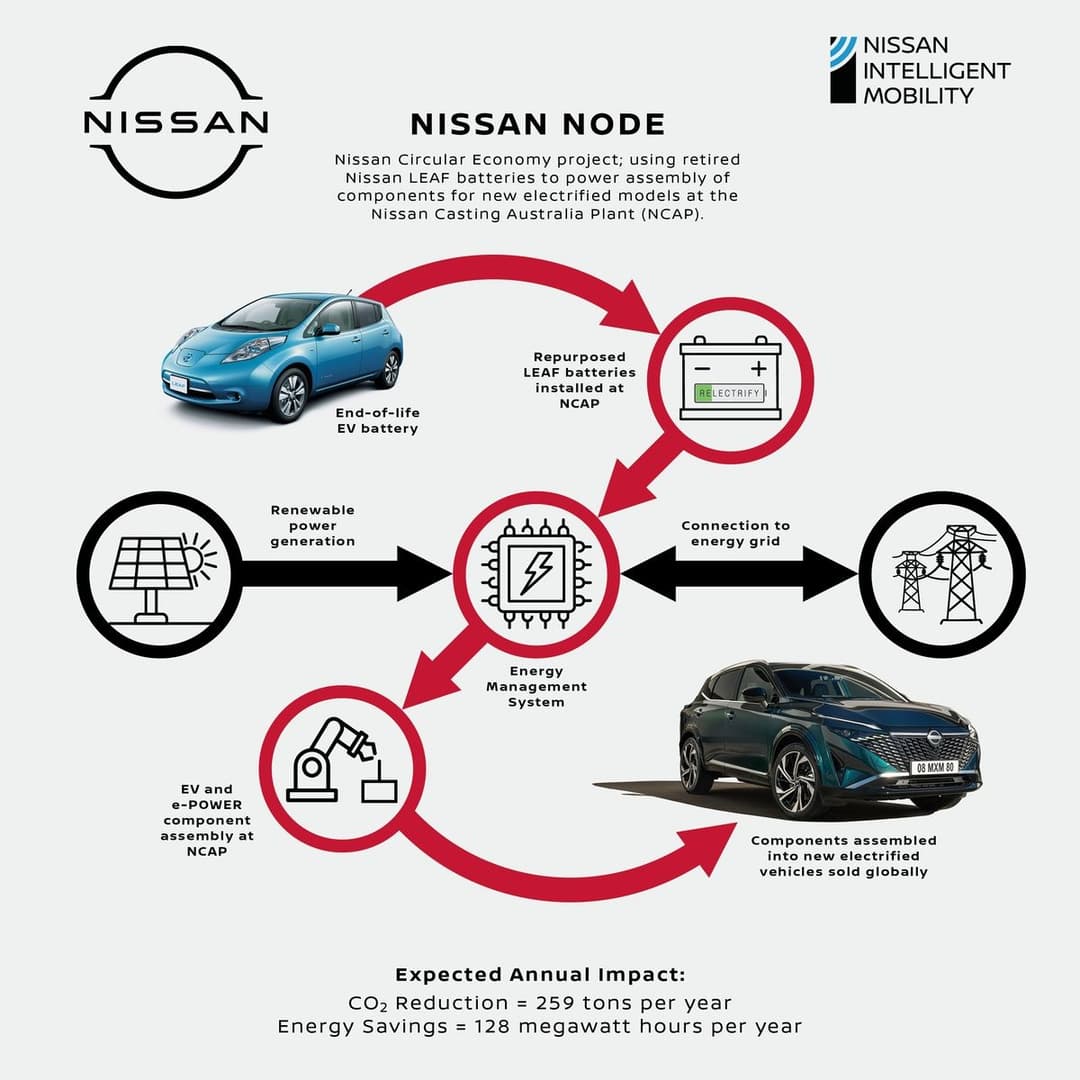

Nissan Australia has launched the Nissan Node project, a groundbreaking initiative that gives old electric vehicle batteries a second life. The project transforms retired Nissan LEAF batteries into a power source for manufacturing operations. This marks a significant step in the automotive industry's shift toward circular economy practices.

What Is the Nissan Node Project?

The Nissan Node project is a Battery Energy Storage System that uses nine repurposed Gen 1 Nissan LEAF batteries. These batteries are installed at the Nissan Casting Australia Plant in Dandenong, Victoria.

The system is charged by a new solar array installed at the facility. The stored energy powers production equipment and electric vehicle chargers on site. This creates a closed-loop energy system that reduces reliance on grid electricity.

Environmental Impact

Environmental Impact

The Nissan Node project delivers measurable environmental benefits. The system will cut 259 tons of CO2 emissions annually. It will also save 128 megawatts of energy each year.

Andrew Humberstone, Managing Director of Nissan Australia, emphasized the significance of the project. "We've been pioneering EV batteries for over a decade, and now we're pioneering second-life initiatives for those batteries," he said.

The Nissan Casting Australia Plant

The Nissan Casting Australia Plant was established in 1982. Today, over 50 percent of its operations are dedicated to producing components for electric and hybrid vehicles.

The facility is Australian Made certified and carries the kangaroo symbol. Every Nissan LEAF sold globally contains components manufactured at this plant. The facility also produces parts for the 2026 Nissan QASHQAI e-POWER.

The ARIYA Connection

The Nissan ARIYA represents the brand's latest electric vehicle lineup. The all-electric SUV uses components manufactured at the Nissan Casting Australia Plant.

Nissan has recognised the Australian facility as a center of manufacturing excellence within its global network. The plant's role in producing EV components positions it as a key player in Nissan's electrification strategy.

Partnership with Relectrify

Melbourne-based company Relectrify developed the battery management and inverter technology for the Nissan Node project. Their ReVolve Battery Energy Storage System is the first of its kind to use end-of-life LEAF batteries.

Jeff Renaud, Nissan's Vice President for Sustainability and Government Affairs, highlighted the importance of Australian innovation. "This project showcases Australian innovation and demonstrates our commitment to carbon neutrality," he said.

What This Means for EV Batteries

The Nissan Node project demonstrates viable second-life applications for electric vehicle batteries. When EV batteries reach the end of their automotive life, they still retain significant capacity for stationary energy storage.

This approach supports circular economy principles by extending battery lifespan and reducing waste. It also positions Australia as a leader in battery recycling and repurposing innovation.

This marks an important step toward carbon neutrality for the automotive industry. The project demonstrates practical solutions for end-of-life EV batteries and shows how manufacturers can integrate sustainability into their operations.

About the author

Stay up to date with the latest EV news

- Get the latest news and update

- New EV model releases

- Get money savings-deal